Lifting Capacity : Crane capacity- 200 MT

(Hydraulic Lifting arrangement for heavier loads up to 250 MT)

Shop covered area: 43,000 Sq. Meter (51,427 Sq. yards)

Total plant area: 250,000 Sq. Meter (298,998 Sq. yards)

Forming

Rolling - Thickness 300mm (12 inches)

Welding

Narrow Gap Welding with seam tracking

Strip Cladding using single as well as double layer technique

Automatic small diameter nozzle cladding.

Twin wire and tandem head welding

SAW, SMAW, TIG, and MIG etc.

Over 850 WPS and 1000 PQR

Drilling

Thickness up to 1000 mm (40 inches) using deep hole CNC Drilling machine

Heat Treatment

Four Gas Fired Furnaces

Size upto: 4500 mm x 4000 mm x 14500 mm

(15 ft. x 13 ft. x 48 ft.)

Stress Relieving, Annealing, Quenching and Tempering as well as Solution Annealing of Stainless Steels

Local Stress Relieving by Electrical Resistance Method

Stress Relieving by Internal Firing Method

Stress Relieving of large jobs in Temporary Furnace

Radiography

Cobalt 60 for Radiography up to 200 mm (8 inches)

Testing

Tensile testing including Elevated Temperature Testing up to 800 Degree Centigrade ( 1470 Degree F)

Impact Testing up to (-) 196 Degree Centigrade (-320 Degree F)

Insitu Alloy Analyzer

Metallurgical Microscope X-2000 with Photography facility

Ferrite Measurement

Recordable/ Mechanized Ultrasonic Testing

Magnetic particle Testing

Liquid Penetrant Testing

Holiday Testing for Painting

IGC Testing

Complete laboratory supported by spectrometer

Codes & Standards

ASME Section 1

ASME Section VIII Division 1, 2 & 3

AD Merck Blatter

PD - 5500

TEMA

Indian Boiler Regulation

Packing & Forwarding

View of shop floor

View of shop floor

160 mm (6 5/16 inches)

Plate being Hot Rolled

160 mm (6 5/16 inches)

Plate being Hot Rolled

Orbital Welding Machine for

Tube to Tube sheet welding

Orbital Welding Machine for

Tube to Tube sheet welding

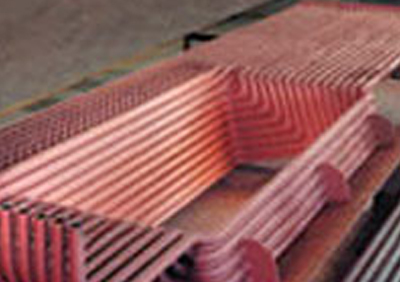

Membrane Panel for 170TPH

Boiler supplied to Indonesia

Membrane Panel for 170TPH

Boiler supplied to Indonesia

Deep hole drilling Machine

(1000 mm thickness)

Deep hole drilling Machine

(1000 mm thickness)

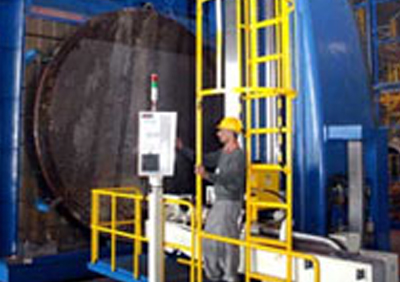

One of our four furnaces

One of our four furnaces

Tensile testing machine

Tensile testing machine