Isgec Titan Metal Fabricators

| Materials of Construction |

|---|

| Tantalum |

| Niobium |

| Zirconium |

| Titanium |

| Pure Nickel |

| Hastelloy |

| High Nickel Alloys (Alloy 20, Alloy600 series, Alloy 800 series etc.) |

| Duplex Stainless Steel |

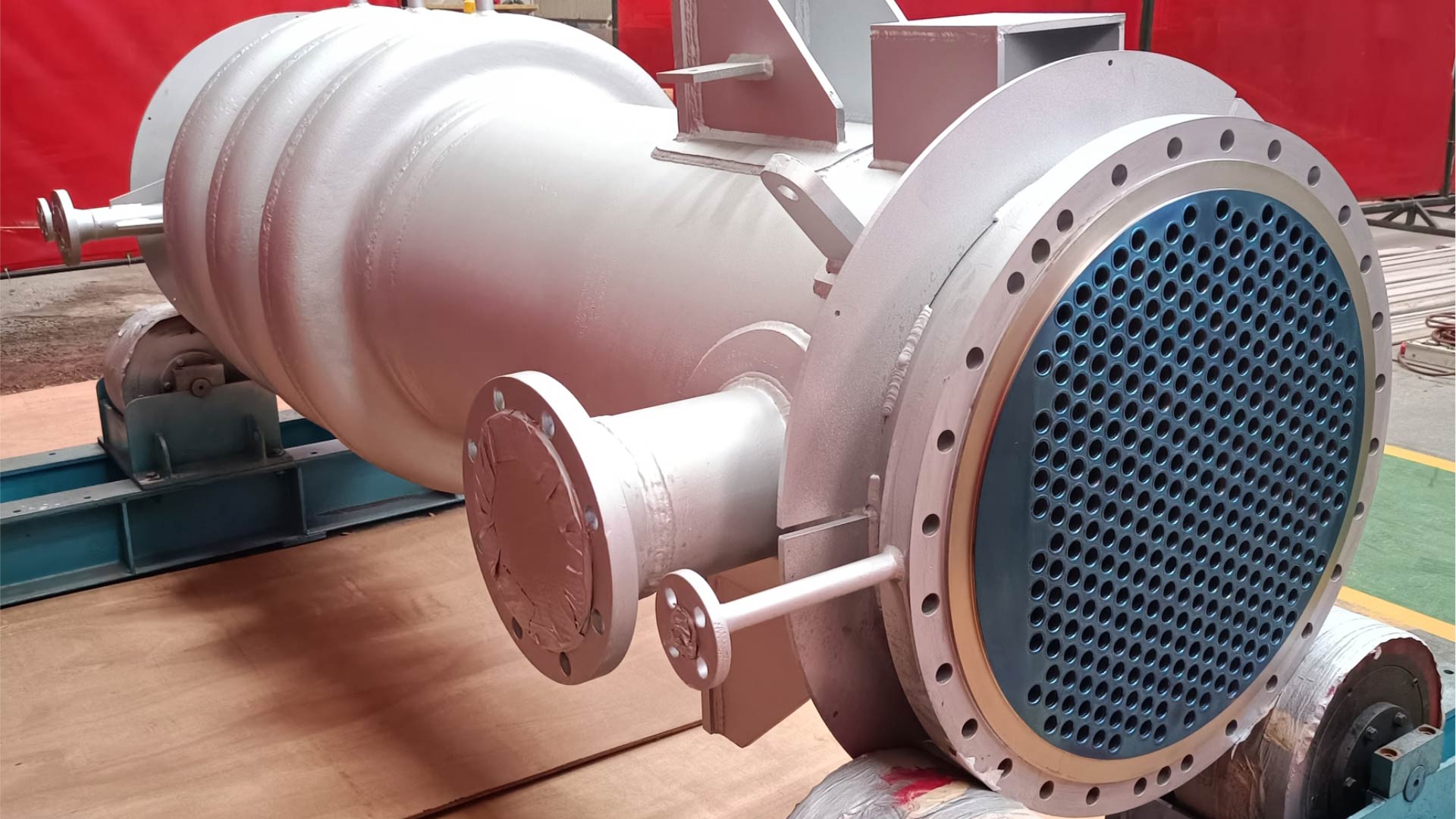

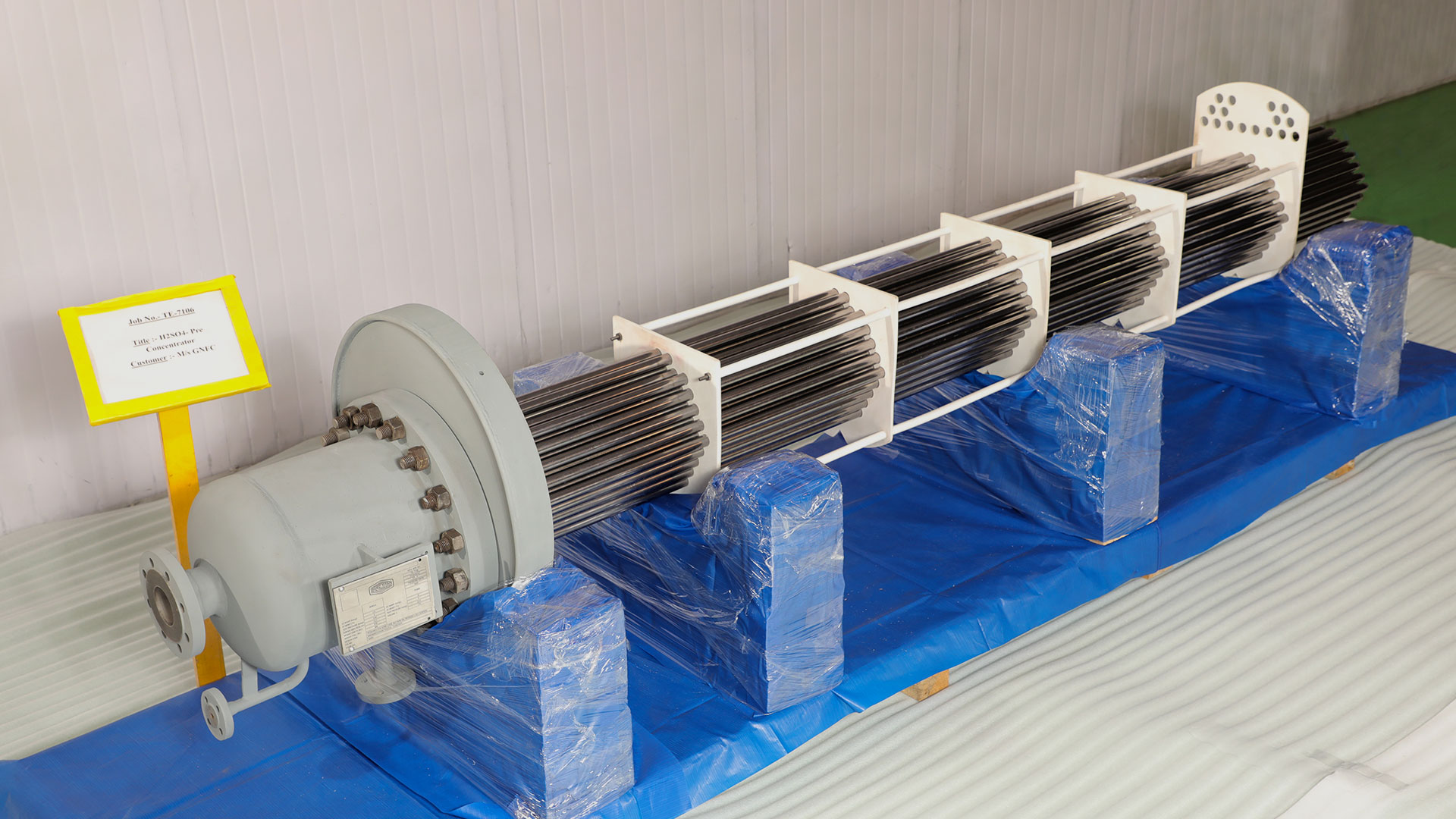

Tantalum Heat Exchanger is a reliable solution for addressing corrosion issues in a wide range of chemical applications. Investing in Tantalum process equipment, particularly Tantalum Heat Exchangers can result in significant long-term benefits, such as reduced downtime, extended equipment lifespan, and increased profitability. Tantalum Shell and Tube/Bayonet Heat Exchangers offer unique advantages over other materials of construction, as they are non-brittle and resistant to cracking, unlike graphite/silicon carbide.

By implementing Tantalum Heat Exchangers, businesses can achieve efficient and reliable operations while maintaining profitability in their corrosive chemical applications in agrochemical, steel pickling, API, fine chemical, bromine, speciality chemical industries.

In chemical processes, the use of titanium heat exchangers has been found to be a cost-effective method for preventing leaks caused by corrosion in process lines. Titanium Heat Exchangers provide extended service life, eliminate downtime and spare parts inventory, offer superior corrosion resistance, deliver high heat transfer efficiency, accommodate high steam pressure, and eliminate breakage risks due to fully-welded metal construction.

Titanium is highly resistant to corrosion because it quickly forms a protective layer when it comes into contact with air or moisture. This layer can repair itself when exposed to moisture or oxygen. Because of these properties, titanium is commonly used in making equipment for various industrial processes.

Zirconium is a highly corrosion-resistant material used in the chemical processing industry. Zirconium Heat Exchangers are cost-effective and can operate for decades when properly maintained. They offer an extended service life, eliminate expensive downtime, require no spare parts inventory, provide superior corrosion resistance, deliver high heat transfer efficiency, accommodate high steam pressure, and eliminate breakage due to their fully-welded metal construction.

Zirconium finds applications in various equipment, such as reboilers, evaporators, tanks, trays, packings, reactor vessels, pumps, valves, and piping. It is particularly important for handling chemicals like acetic acid, formic acid, hydrochloric acid, melamine, sulfuric acid and nitric acid.

Hastelloy Heat Exchangers are a cost-effective choice throughout their lifespan. They outperform heat exchangers made of other materials and have a longer service life. This means less downtime and no need for spare parts inventory. They offer excellent resistance to corrosion, high heat transfer efficiency, and can handle high steam pressure. Additionally, their fully-welded metal construction prevents breakage during handling, installation, and operation.

Hastelloy serves various industries, including chemical process, petrochemical, oil & gas, pharmaceutical, geothermal, sea water, water desalination, LNG (liquefied natural gas), biomass, mining, utilities, nuclear power, and solar power.

| Equipment Fabricated |

|---|

| Shell & Tube Heat Exchangers |

| Bayonet Heat Exchangers |

| Pressure Vessels |

| Reactors |

| Columns/ Towers |

| Internals |

| Piping & Piping Components |

| Custom Fabrication |